Project Information

- Partner: CSIR

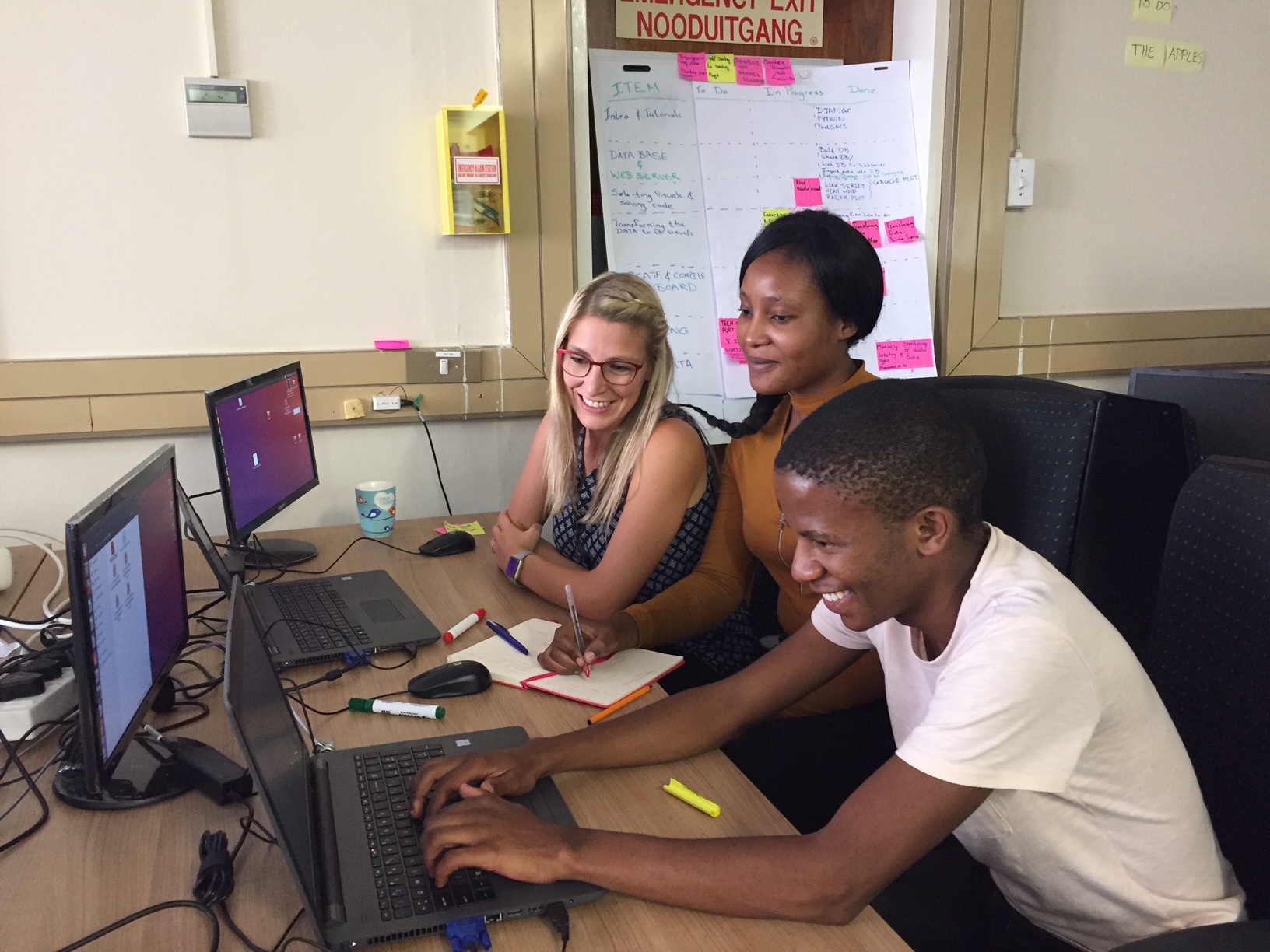

- Students: Clotilda Langutani Mandlazi (UL), Nicolene Roux (Wits) and Boitumelo Mahlobo (UP)

- Project Lead: Gideon Ferreira and Laura Martinus

- Project Mentors: Vongani Maluleke

- Year: 2017/2018

Project Description

South Africa is highly dependent on its rich mineral resources for its Gross Domestic Product (GDP), but together with this important benefit is the fact that the South African Mining Industry is one of the country’s most dangerous industries to work in. South Africa has some of the world’s oldest and deepest mines and although injuries from falling rocks are statistically decreasing, accidents related to seismic activity and rock bursts (rocks that are under pressure explodes) are increasing. Rock Pulse aims to reduce these accedents by implementing an early warning system that warns the miners before a FOG occurs.

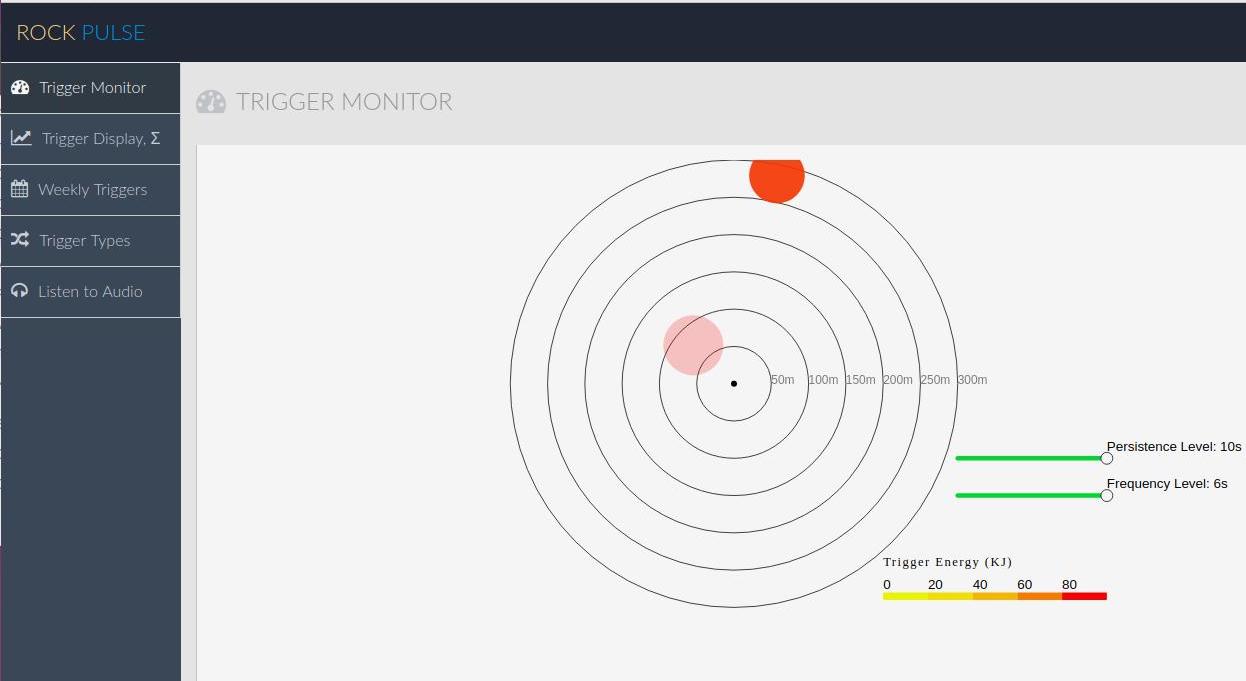

Data is collected in real time underground using a geophone. The data is then interpreted by algorithms in order to identify triggers (potential hazardous events) which eventually set off an alarm initiating an evacuation of a mining section. This data consists of time and date stamps, location data, magnitude counts (mm/s), spectral centroid (Hz) and energy data (J).

The data reveived for the project is from an underground coal mine that uses the long wall mining technique. This technology has reached a level of confidence which assures the validity of the technology, but there are still space for improvements and advances. The CSIR has tasked the DSIDE Rock Pulse team with a twofold task:

- The first being to design a functional dashboard that will be able to informatively display the data collected from the Rock Pulse sensor. The dashboard will be interactive and display the needed graphs that will clearly indicate what the current conditions are underground.

- The second task is to apply machine learning to the RAW data in order to create a model that will be able to distinguish between sounds that are man made and sounds that are non man made. This model will contribute to the accuracy of this technology. Currently, this technology overestimates the alarms, meaning that for every three alarms that goes off, only one was a valid alarm. This is generating a negative response from clients as unnecessary evacuations results in financial implications due to production losses and it also causes distrust in the product. The team’s contribution will therefore enable the technology to distinguish between a crack (valid trigger for potential FOG) and a man made sound setting off the trigger (drilling), and thereby reduce the amount of false triggers.

Dashboard

Team